Worn Again: 40 factories in 2029 to regenerate two million tons of fibers

The British company, founded and piloted by Cyndi Rhoades, has already managed to recover the polyester and cotton fibers from textile waste and is now facing the next phase, which is to scale it up.

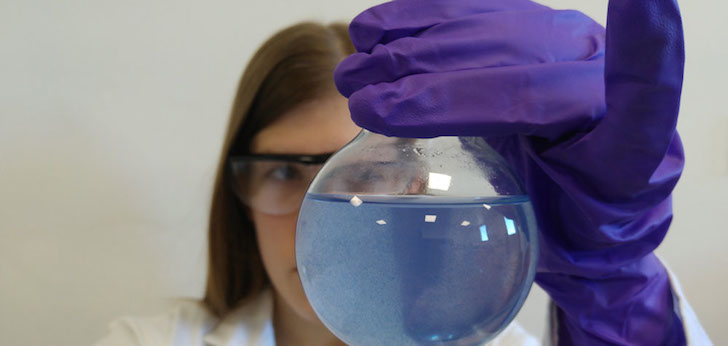

Worn Again shapes the circular industry of the future. The British company, founded and piloted by Cyndi Rhoades, has already managed to recover the polyester and cotton fibers from textile waste and is now facing the next phase: to scale it up. The objective to ten years will be to have forty factories to produce two million tons of regenerated fibers to return them back to the value chain of the textile industry.

The origins of Worn Again were in textile recycling, with the purpose of giving a second chance to the used garments. “But immediately we realized that if we wanted to do something different we had to look for the scale and this should involve the production companies,” explains Rhoades.

The entrepreneur explains that they began to establish the first agreements with manufacturers of work clothes, but notes that her ambition to address the problem was then to look beyond recycling. In 2012, the company understood that the materials could be reused but not rewoven because there were technical limitations.

H & M and Kering were among the first companies to bet on the technology developed by Worn Again to make circularity in textile a reality

Then, in other industries, such as plastic, it was already possible to separate the contaminants in order to focus again on the materials. The purpose of Worn Again was to transfer it to the textile with the challenge of recovering the fibers of the threads to return them back to the value chain with the same quality as the virgins.

Currently, Worn Again is able to recover polyester and cotton, among other materials. It now remains to develop the process under a pilot plan with a view to scaling it up. According to Rhoades, they have set a deadline of two years to resolve it. From there, the next step will be to gain global size.

The distribution giants began to join the project from 2013. The Swedish H&M and the French luxury boiler Kering were among the first to join the project, entering its capital with a view of accelerating research. With time, other fashion groups have joined, as well as other industrial groups.

Among the latest to join this initiative are the Japanese clothing and sports equipment group Asics, the German weaver Sympatex, the German linen manufacturer Dibella, the US brand Dhana and the Mexican groups Diretex and Himes. These alliances allow companies in the sector to have access to certain quantities of raw materials to begin testing with them.

info@themds.com

Validation policy for comments:

MDS does not perform prior verification for the publication of comments. However, to prevent anonymous comments from affecting the rights of third parties without the ability to reply, all comments require a valid email address, which won’t be visible or shared.

Enter your name and email address to be able to comment on this news: once you click on the link you will find within your verification email, your comment will be published.